TitleUsing GIS to Analyze Tracer Test Data

at the Geysers Geothermal Power Plant |

||||||||||||||

|

Author Karly McCrory |

||||||||||||||

AbstractOperators at the Geysers Geothermal Power Plant in

Northern California were faced with the challenge of processing a large

volume of tracer test data on a daily basis. Three methods were evaluated for

processing this data: hand-plotting, CAD, and GIS. Researchers quickly

discovered that GIS had value that the other methods did not: functionality.

Utilizing basic GIS features and combining them with customized user

interfaces automated a previously manual processógreatly reducing the amount

of time and money spent on analyzing tracer test data at the Geysers. |

||||||||||||||

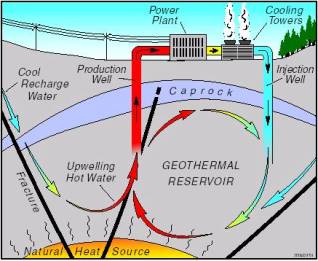

IntroductionThe Geysers is

part of the Clear Lake volcanic range in Northern California. As an active

volcanic area, Geysers is well suited for geothermal

energy. Geothermal energy is harnessed through steam and hot water directly

from the Earth, and can be used to generate electricity (Figure 1).

Figure 1. How a

geothermal power plant works. In 1960, a geothermal

power plant was established at Geysers. Gradually, the Geysers plant (below)

grew to become the largest geothermal development in the world (Kious and

Tilling, 1996).

Photograph

by Julie Donnelly-Nolan, USGS At first, steam

production began only in the north-central region of Geysers, but by 1980

production had gradually spread to the entire stream field. In the mid-1970s,

concerns about the abundance of Geysersí reserves began to emerge. In 1975,

operators began tracer tests at Geysers to track both the dry-out of the

reservoir, and the rate at which the reservoir naturally re-saturates itself

(Beall et al,

2001). When tracer testing began

at the Geysers, tests were only run every two to four years, so there wasnít

a need for a mapping tool other than hand-plotting. Over the years, the

frequency of tracer tests increased dramatically. Currently, the return time

for a tracer test is often less than one day for nearby wells (Nash and Adams,

2001). The results from a day of testing must be analyzed to

determine which wells are tested the following day. Each tracer test

generates a large amount of data that must be mapped and interpreted

efficiently. This paper discusses the different methods used for visualizing

tracer test data, and how GIS reduced costs and increased efficiency at the

Geysers. |

||||||||||||||

BackgroundGIS has many

capabilities and a wide variety of applications, such as the ability to tie a

location on a map to a table of attributes, and the ability to query said

table. Yet given the obvious benefits and applications of GIS in the

geothermal industry, it has not been widely adapted. The Energy & Geoscience Institute (EGI)

in Salt Lake City, Utah has been at the forefront of bringing GIS to the

geothermal industry. The data

used in this project was not hard to find, however it was also not plentiful.

The literary and data sources used for this project were available over the

Internet. The two main publications used came from the Geothermal Resources Council Transactions, a collection of papers

for a given year. I also tried to find information about other geothermal plants that

may use GIS to map tracer test results, but I could not find any. It seems

that although the geothermal industry has a great need for this tool, they

are far behind in actually utilizing it to its fullest extent. |

||||||||||||||

|

Methods The Geysers operators tasked the

researchers at EGI with finding a way to effectively manage tracer test data.

The researchers decided to evaluate three approaches to solve the Geysers

problem: (1) hand-plotting, (2) computer aided design (CAD) software, and (3)

GIS. First they evaluated the approach that

the Geysers operators were already using: hand-plotting. The first drawback

of the hand-plotting method was an obvious oneóthe large amount of data from

a single tracer test was overwhelming to conquer with such a slow and tedious

process. Researchers also found that many times the map maker would try to

draw the map to a degree of accuracy that goes beyond the definition of an

isoline, adding even more time to an already lengthy process (Nash and Adams,

2001). Researchers

then decided to look to computers to solve their problem. They decided to

evaluate two types of computer mapping programs: AutoCAD LT‚ 2000i with Autodesk CAD Overlay‚ versus ArcView 8.1

with ArcView Spatial

Analyst‚. While both

programs provided a method for digital mapping, thereby decreasing the amount

of time spent on map creation, ArcView offered functionality that CAD did

not. With ArcView, not only could the user create and isarithm

map quickly, they could also link points on the map to an attribute table.

Even further, they could superimpose the isarithm map on satellite,

topographic, or geologic maps of the area (Nash and Adams, 2001). By

utilizing the query function in ArcView, operators were also able to quickly

and efficiently analyze the results of the tracer tests. |

||||||||||||||

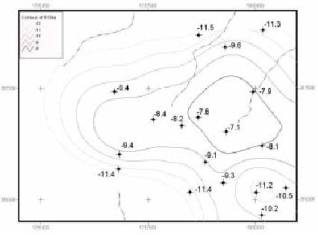

ResultsUsing ArcGIS Spatial Analyst‚ to create isolines, researchers found that with

some initial experimentation, good statistical surfaces could be generated

very quickly (Figure 2). Numeric values are given next to sampled wells for

comparison to the computer-generated contours. Because the contouring

parameters can be reset, several new maps can be created for comparison in a

matter of a few minutes. The user only has to repeat the process a few times

to get a feeling for the proper parameters, enabling them to generate new

maps even more quickly (Nash and Adams, 2001). |

Figure 2. Isarithm

map. |

|||||||||||||

|

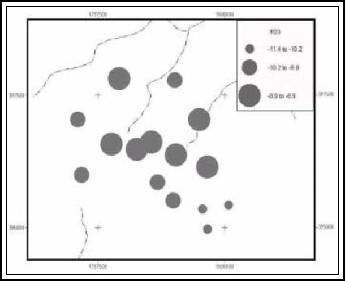

Figure 3.

Classified graduated circle map. |

Researchers also experimented with classifying attributes in different

ways, along with different visual representations of those classifications.

They found that if a high degree of spatial accuracy was needed, graduated

circles were preferred (Figure 3). Because the human eye is able to easily

differentiate between the sizes of the circles, visual comparisons of the

data were made much easier. Researchers also experimented with combining

graduated circles with other shapes and graduated color to represent multiple

data sets per sample point (Figure 4) (Nash and Adams, 2001). |

|||||||||||||

|

Figure 4. Combination of multicolored graduated

circles and graduated symbol map. |

||||||||||||||

|

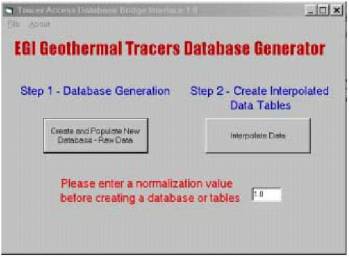

GIS was proving to be a useful tool for

analyzing and mapping the tracer test data. However, researchers soon

discovered that the Microsoft Excel‚ spreadsheet they were using was not

the best method for importing data into ArcView. Because the Excel format was

not favorable, the data had to be reformatted and exported into a dBase table

or comma delimited text file for import into ArcView. Researchers decided to

develop a new database format that would be used as an input for a new bridge interface

(Figure 5) (Nash and Adams, 2001). |

Figure 5. Bridge interface. |

|||||||||||||

The bridge interface is then used to create a new

database in Microsoft Access‚. Both raw tracer and steam flow data are needed for the bridge

interface to generate the new database and tables. The bridge interface tool

makes the process of database generation very fast and easy to use. In

addition, the interface can be used with any GIS software that facilitates an

SQL connection to Access. The format for input of the data is:

The Well_Names field

is used as the unique identifier for any table relations or joins. When the Access

database is generated, it contains the following seven tables: 1) raw tracer

data, 2) normalized data, 3) log transformed normalized data, 4) interpolated

data, 5) cumulative values of interpolated data, 6) normalized interpolated

data, and 7) log transformed normalized interpolated data. The user defines

the normalization value, and the interpolation process estimates missing

values. |

||||||||||||||

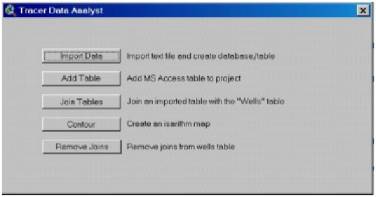

The bridge interface is linked to the Tracer Data

Analyst (Figure 6), a customized object oriented user

interface within ArcView. This interface can call up the bridge interface,

rapidly create SQL connections to tables that have been generated, and

facilitated automatic joins to generate isarithmic maps. To make map

generation possible, a table consisting of well names and XY coordinates must

be added.

|

|

|||||||||||||

ConclusionsIn the end, GIS proved a far better solution for the

Geysers Geothermal Power Plant than either hand-plotting or CAD did. The main

reason behind this is the functionality that GIS brings to cartography. By

giving the users the ability to join and query tables, use different

attribute classifications to increase visual effectiveness, and the

capability to overlay maps, GIS became a very effective solution to the

Geysers problem. Researchers furthered this effectiveness by customizing user

interfaces; thereby greatly reducing the man-hours needed to process tracer

test data. |

||||||||||||||

ReferencesBeall, J.J., M.C.

Adams and J.L.B. Smith, 2001. Geysers Reservoir Dry Out and Partial

Resaturation Evidenced by Twenty-Five Years of Tracer Tests. Geothermal

Resources Council Transactions, v. 25, p. 725-729.

Kious, W.J. and R.I. Tilling, 1996.

This Dynamic Earth: The Story of Plate Tectonics. U.S. Geological Survey

General Interest Publication. Nash, G.D. and M.C. Adams, 2001.

Cost-Effective Use of GIS for Tracer Test Data Mapping and Visualization. Geothermal

Resources Council Transactions, v. 25, p. 461-464. Data Reference: http://www5.egi.utah.edu/Geospatial_Data/The_Geysers__California/the_geysers__california.html |

||||||||||||||